We understand what customer needs, a good quality tool can save a lot of cost for mass production.

Each mold we made hope can become a Money Printer for customer.

Smooth is ISO and IATF certificated company.

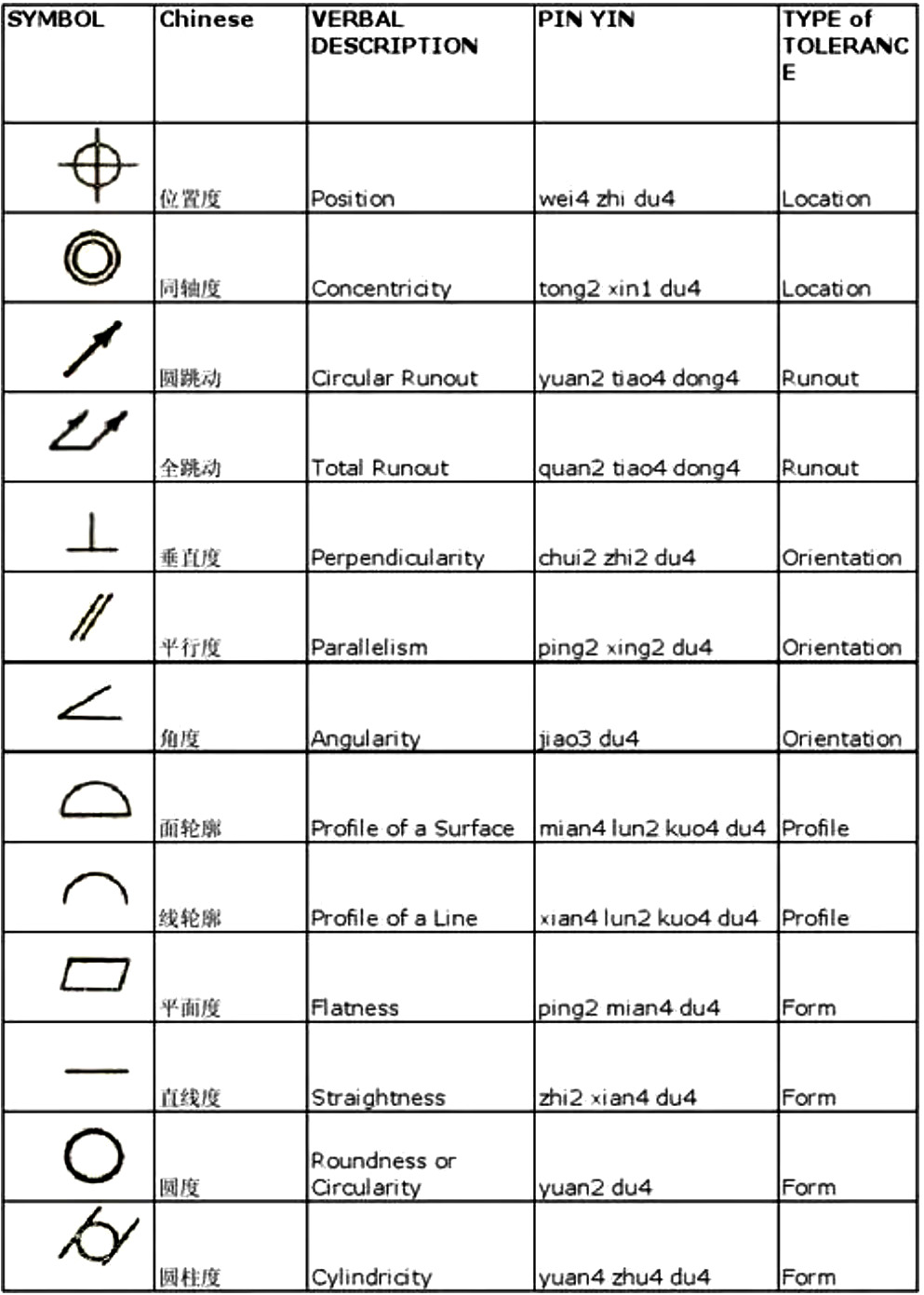

※ GD&T drawing analysis

After got customer’s GD&T drawings, we will study it. Some time for critical places, we need keep some safe steel on the mold. After get OTS and inspection, we can adjust the critical dimensions to avoid welding.

※ Design Process

Design is critical for quality control. Good design ensure good quality. A good design need fulfill these:

➜ Easy to Manufacture

➜ Easy to Assemble and Disassemble

➜ Easy to maintain

➜ Easy to adjust the tolerance

➜ Structure simple and reliable

➜ Totally match customer injection machine

During the design process, we will communicate with customer about all concerns.

A complete checking list is needed during whole design process.

※ Machining

Use appropriate machining method is very important to get correct precision parts. Of course good precision machines are the basis needs.

But sometimes a good machining method process no need very high precision machines.

So, good design plus good machining method is the way to get precise mold parts.

A Critical issue for control the quality of die casting mold is, we need using EDM to making the part form as less as possible.

As EDM will damage the steel surface, and maybe polishing can’t remove the harden skin completely. That will cause the steel may have some small cracks earlier than estimation.

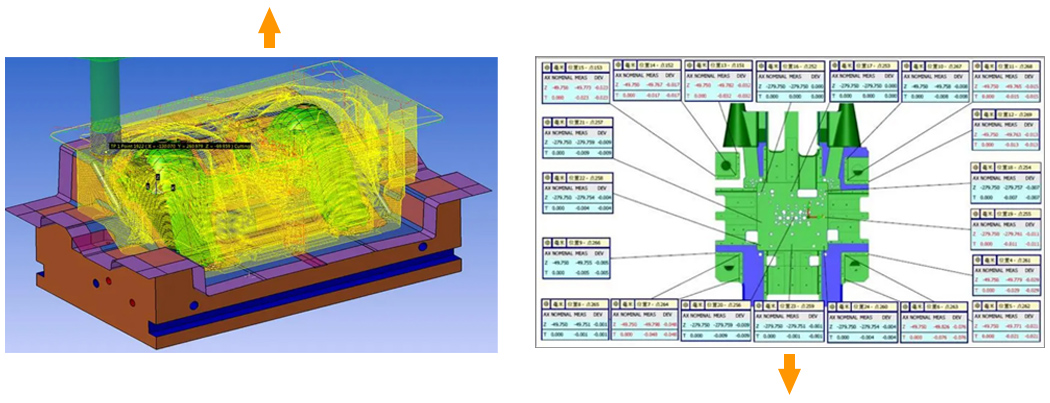

※ Mold details Inspection

After finished the mold detail parts, inspection is certain needed. Checking if all result match the design tolerance and precision, will save a lot of time to bedding the mold.

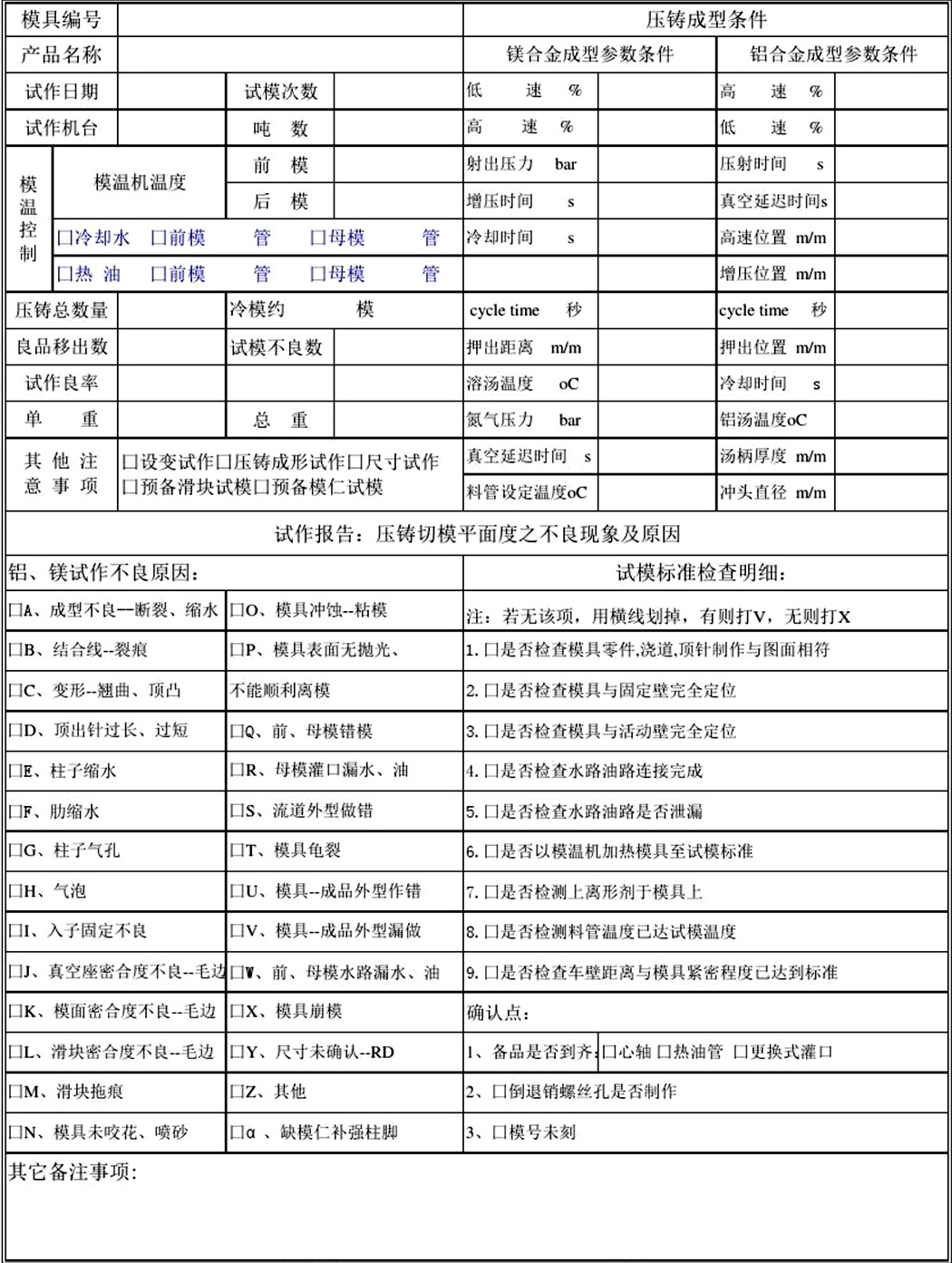

※ Trial

In most cases, customer will not attend the trial. That makes some customers worrying about if the process is good or not.

Smooth Project team will handle this and ensure customer know everything during the trial process. Project manager will stay at the Die casting machine, and take pictures and videos. Also will record all issues during the trial. Also will arise how to improve, or solution for the problems.

The trial report which sending to customer will be English and Chinese Version.

※ Shipping

Have to say, shipping also is very important for customer.

If all is good, but the mold have damaged on the way. That will also cause big problems.

Smooth understand this, now we have our standard packing process after lots of lessons.

Below is some pictures show what we are dealing with this: